Reactive VS Dyes

Reactive VS Dyes Specification

- Purity

- 99%

- Resistance

- Excellent Light and Washing Fastness

- Shape

- Powder/Granular

- Strength

- 100% Standard

- Smell

- Odorless

- Melting Point

- Decomposes

- Moisture (%)

- <1%

- HS Code

- 32041600

- Rubbing Resistance

- Good

- Taste

- Odorless

- Grade

- Industrial & Textile Grade

- Structural Formula

- Variable (based on specific dyestuff)

- Solubility

- Easily Soluble in Water

- Solvent Color

- Matches Standard

- Water Resistance

- Excellent

- Other Names

- Reactive Vinyl Sulfone Dyes

- Shelf Life

- 2 Years

- Application

- Dyeing of Cellulosic Fibers such as Cotton, Viscose, and Linen

- Molecular Formula

- Variable (depends on specific color index)

- Type

- Reactive Dye

- Usage

- Textile Industry

- Physical Form

- Powder & Granules

About Reactive VS Dyes

Our company is one of the noteworthy processors, exporters and suppliers of supreme quality Reactive VS Dyes that are basically vinyl sulphone based dyes. Proposed dyes are are basically a class of highly colored organic substances. These dyes are available in a variety of colors and shades in liquid state to be used with paper, leather and textile to match the requisites of the clients. Our seasoned chemists process offered products by making use of quality-tested basic chemicals at our technically sound processing units. Further, clients can avail these Reactive Vinyl Sulphonate Dyes(VS) Dyes from us at an economical price range.

Features:

-

Superior fastness properties

-

Optimum solubility

-

High brilliancy

-

Precise compositions

| Product Name | Colour Index No. | CAS No. |

| TURQ.BLUE G | BLUE 21 | 12236-86-1 |

| BLACK B | BLACK 5 | 17095-24-8 |

| YELLOW FG | YELLOW 42 | 12226-63-0 |

| YELLOW GR | YELLOW 15 | 12226-47-0 |

| ORANGE 3R | ORANGE 16 | 20262-58-2 |

| RED F3B | RED 180 | 72828-03-6 |

| RED RB | RED 195 | 93050-70-4 |

| BLACK N 150 | Mixture | |

| BLACK HFGR | Mixture | |

Wide Application Versatility

Reactive VS Dyes are ideal for the dyeing of a broad range of cellulosic fibers, including cotton, viscose, and linen. Their robust anionic nature and compatibility with various auxiliaries make them suitable for both large-scale industrial processes and intricate textile applications, providing flexibility to manufacturers and exporters operating in India and beyond.

Exceptional Color and Performance

These dyes distinguish themselves through vibrant hues and exceptional resistance to light, water, and washing. Their high dispersibility and standard strength ensure uniform coloration and minimal waste, enhancing the quality and durability of finished textiles. The recommended exhaust temperature range of 60C to 80C further optimizes dye uptake and fabric performance.

Efficient Manufacturing and Storage

Produced through advanced azo and copper phthalocyanine methods, Reactive VS Dyes are consistently reliable. Their stable, easily water-soluble powder or granule form simplifies storage and handling. For best results, store in a cool, dry, and ventilated place to maintain dye integrity and extend shelf life up to two years.

FAQs of Reactive VS Dyes:

Q: How are Reactive VS Dyes best applied to cellulosic fibers?

A: Reactive VS Dyes are primarily used for dyeing cellulosic fibers such as cotton, viscose, and linen. For optimal results, use the recommended exhaust temperature of 60C to 80C and compatible auxiliaries to achieve uniform dye uptake and vibrant color.Q: What makes Reactive VS Dyes compatible with other reactive dyes and auxiliaries?

A: These dyes possess an anionic ionic nature, which ensures they blend seamlessly with other reactive dyes and standard auxiliaries without causing precipitation or shade inconsistencies, enhancing process flexibility.Q: When should these dyes be used for the best color fastness?

A: For superior light and washing fastness, Reactive VS Dyes should be used in controlled dyeing processes under stable conditions, including precise temperature regulation and adequate mixing, as guided by recommended textile industry protocols.Q: Where should Reactive VS Dyes be stored to maintain stability and shelf life?

A: Store the dyes in a cool, dry, and well-ventilated space, ideally inside their original 25 kg HDPE bags with an inner liner, to preserve their quality and extend shelf life up to two years.Q: What are the primary benefits of using Reactive VS Dyes in textile manufacturing?

A: Primary benefits include vivid color range, high purity, excellent water solubility, substantial resistance to color fading, good dispersibility, and compatibility, resulting in durable and eye-catching textiles.Q: How is the manufacturing process for Reactive VS Dyes executed?

A: Reactive VS Dyes are manufactured using advanced azo and copper phthalocyanine synthesis methods, enabling precise formulation for different color indices and high stability, suitable for industrial and textile-grade applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reactive Dyes Category

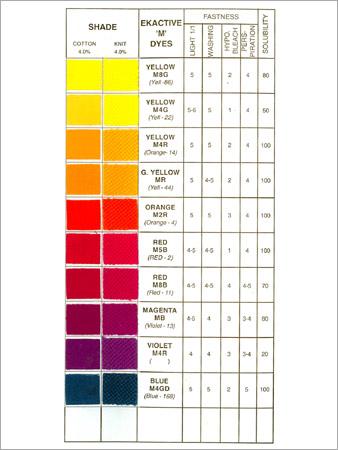

Reactive M Dyes

Moisture (%) : 2.0%

HS Code : 32041600

Melting Point : Decomposes before melting

Physical Form : Powder

Rubbing Resistance : other, Good

Purity : 99% Min

Reactive HE Dye

Moisture (%) : <1.0% (max)

HS Code : 3204.16

Melting Point : >250C (depending on dye)

Physical Form : Other, Powder or Granular

Rubbing Resistance : other, Good (varies by fabric and application)

Purity : Up to 99% (varies by grade)

Reactive ME Dyes

Moisture (%) : 0.5% max.

HS Code : 32041600

Melting Point : >180C (decomposes)

Physical Form : Other, Powder or Granules

Rubbing Resistance : other, High (Dry & Wet)

Purity : 99% min.

|

NAVIN CHEMICALS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese