Reactive ME Dyes

Reactive ME Dyes Specification

- Strength

- 100% Standard

- Purity

- 99% min.

- Molecular Formula

- Varies depending on specific dye

- Structural Formula

- Varies; typically contains vinyl sulphone and monochlorotriazine groups

- Shelf Life

- 2 years in sealed condition

- Size

- Custom packaging (10kg, 25kg)

- Rubbing Resistance

- High (Dry & Wet)

- Smell

- Odorless

- Solubility

- Easily soluble in water

- Grade

- Industrial / Textile Grade

- HS Code

- 32041600

- Application

- Dyeing of cotton, viscose, and blended fabrics

- Moisture (%)

- 0.5% max.

- Solvent Color

- Color varies (according to dye color)

- Shape

- Fine crystalline or powder

- Melting Point

- >180C (decomposes)

- Water Resistance

- Excellent

- Resistance

- Excellent washing, light, and perspiration fastness

- Usage

- Textile dyeing, printing, and coloration of cellulose fibers

- EINECS No

- Variable (specific to dye component)

- Physical Form

- Powder or Granules

About Reactive ME Dyes

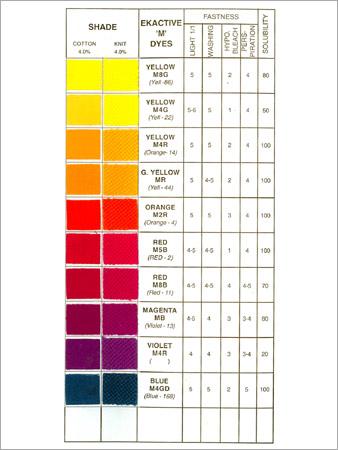

Clients can buy from us optimum quality assortment of Reactive 'ME' Dyes that is majorly used for coloring on wood, paper, tissue and packaging materials. These work via a colorant mechanism since it contain two or more reactive groups. Widely used in various textile industries for dyeing various kinds of fabrics, this dye is Formulated at our in-house processing units using optimum quality basic chemicals. The offered Reactive Mild Exhaust (ME) Dyes is made available for clients in different quantity packs and various colors to suit their exact needs.

Features:

-

High chemical stability

-

good fastness properties

-

high level fixation

-

High Exhaust low Temperature

| YELLOW M4G | YELLOW 22 | 12226-49-2 |

| YELLOW M8G | YELLOW 86 | 61951-86-8 |

| YELLOW M3R | ORANGE 86 | 83929-91-3 |

| YELLOW M4R | ORANGE 14 | 12225-86-4 |

| GOLDEN YELLOW MERL | YELLOW 145 | 93050-80-7 |

| YELLOW ME4GL | YELLOW 186 | 84000-63-5 |

| RED ME4BL | RED 195 | 93050-70-4 |

| RED ME6BL | RED 250 | 125380-49-1 |

Exceptional Dye Performance for Textiles

Reactive ME Dyes provide vibrant and even coloration for a wide range of cellulose fibers, including cotton and viscose. With high solubility in water and a high fixation rate, these dyes ensure deep, consistent shades as well as excellent resistance to washing and sunlight. Thanks to their compatibility with textile auxiliaries and adaptability to different dyeing methods, they cater to various production needs in textile industries.

Versatile Application Methods

Designed for flexibility, Reactive ME Dyes support multiple dyeing techniques such as exhaust, pad, and continuous dyeing. This versatility allows manufacturers and suppliers to efficiently process a range of fiber blends while maintaining optimal color quality and fastness. The dyes are highly suitable for discharge printing and are packed in customizable sizes to accommodate different commercial scales.

Safe Handling and Long Shelf Life

These dyes remain stable under normal conditions, provided they are stored in a cool, dry, ventilated space away from direct sunlight. Standard HDPE packaging with an inner liner ensures product integrity for up to two years. Odorless and with minimal moisture content, Reactive ME Dyes are easy to handle and transport, making them a preferred choice for global distributors and local textile producers alike.

FAQs of Reactive ME Dyes:

Q: How should Reactive ME Dyes be stored to maintain their quality?

A: Reactive ME Dyes should be stored in a cool, dry, and well-ventilated area, protected from direct sunlight. Proper storage in sealed HDPE packaging ensures a shelf life of up to two years and maintains their original quality.Q: What textile applications are suitable for Reactive ME Dyes?

A: These dyes are widely used for dyeing and printing cellulose fibers, including cotton, viscose, and their blends. They are especially well-suited for exhaust, pad, and continuous dyeing, as well as for discharge printing techniques.Q: When is it optimal to use these dyes during textile production?

A: Reactive ME Dyes should be applied during the dyeing or printing phases, particularly when even color distribution, high fixation rates, and fastness to washing and light are required for high-quality textile products.Q: Where can these dyes be utilized within the textile industry?

A: These dyes are suitable for use in textile dyeing and printing facilities, garment manufacturing, and processing units catering to international and domestic marketsespecially in regions like India, where they are produced and distributed.Q: What process conditions are recommended for dyeing with Reactive ME Dyes?

A: The recommended exhaust dyeing temperature is typically 60C. The dyes exhibit medium reactivity, allowing a broad temperature application range and compatibility with most textile auxiliaries for level dyeing.Q: How does the usage of these dyes benefit textile manufacturers?

A: By offering excellent color levelness, strong fixation rates on cellulose fibers, and high resistance to washing, sunlight, and perspiration, these dyes help manufacturers produce durable and vibrant textile products, reducing re-dyeing and improving product longevity.Q: What makes Reactive ME Dyes compatible with a variety of dyeing methods and auxiliaries?

A: Their anionic ionic nature and medium reactivity ensure compatibility with most textile auxiliaries, while their solubility and stability support various dyeing methods, enabling manufacturers to achieve consistent results in different production setups.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Reactive Dyes Category

Reactive M Dyes

Solvent Color : As per shade (varies)

Shape : Other, Powder

Melting Point : Decomposes before melting

Resistance : Other, Good wash and light fastness

Water Resistance : Excellent

Physical Form : Powder

Reactive HE Dye

Solvent Color : Specific to dye tone (varies by color)

Shape : Other, Crystalline/Powdered

Melting Point : >250C (depending on dye)

Resistance : Other, Good light & washing fastness

Water Resistance : Excellent

Physical Form : Other, Powder or Granular

Reactive VS Dyes

Solvent Color : Matches Standard

Shape : Other, Powder/Granular

Melting Point : Decomposes

Resistance : Other, Excellent Light and Washing Fastness

Water Resistance : Excellent

Physical Form : Other, Powder & Granules

|

NAVIN CHEMICALS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese